We have been a reliable and flexible partner for industrial companies in the region as well as suppliers of companies worldwide for many years. Our customers come from many European countries, USA, Russia, United Arab Emirates and more. Whether as an extended workbench for welding, edging, bending and assembly work or as complete manufacturer of your products and components. With our fleet of vehicles we are also able to carry out many regional logistics services independently.

Corrosion protection and appearance are decisive requirements for our products. That is why we only work with high-quality and environmentally conscious partner companies. We make use of the latest developments in surface technology, the following processes are used:

- Powder coating

- Electroplating

- Hot-dip galvanizing

- Paint

- Staining

- Electrochemical polishing

Pipe form constructions in every design. There are virtually no limits to your product thanks to laser cutting and welding of shaped pipes.

- Pipe and shaped pipe cutting (classic)

- Laser cutting of tubes and shaped tubes

- Welding (WIG/MAG/MIG)

- Rolling of shaped pipes and round pipes

- Straightening

Our employees are certified in accordance with EN 281-1:2010 and our processing quality meets the high requirements of our customers from a wide variety of sectors.

- Manual welding (MAG/WIG/MIG)

- Automated welding

- Spot welding

Through our cooperation with a wide variety of customers in a wide variety of industries, we have acquired a great deal of know-how in the production of finished products and in the handling of projects. You will profit from our know-how from the moment the order is placed up to the final assembly.

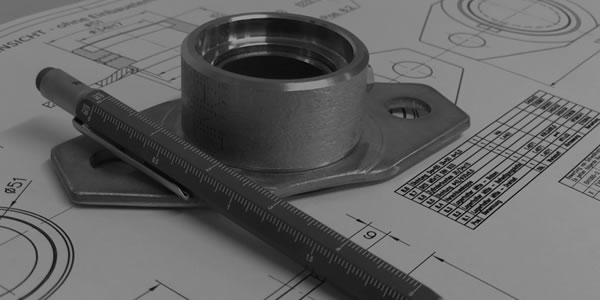

The production of components is one of our main focuses. The products made of different products and materials as well as surfaces are carried out by us on request until dispatch.

Wire processing is a special competence of our company. From prototype construction to series production, we have no limits.

- Alignment

- Cutting to length

- Spot welding

- CNC spot welding

- Cutting

- Laser cutting (oxygen/nitrogen cutting)

- Water Jet Cutting

- Grinding, brushing, satin finishing (stainless steel)

- Single-part production

- Series production

- Cutting (classic)

- Plasma cutting

- Edging

- Punching

- Rolling

- Press-in

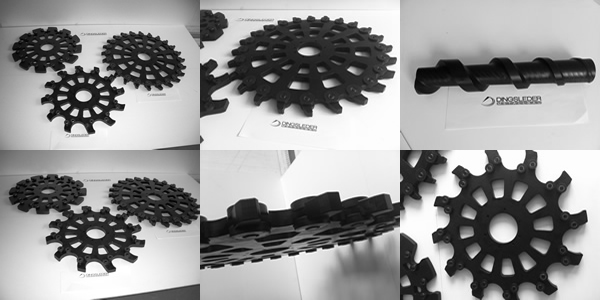

The Tooling division is fully integrated and covers all products related to testing and inspection machines. We are able to fully implement equipment such as inlet screws and spare parts for ISM, CO, M1 and CHECK+ machines. At this point we would also like to point out that we can draw on many years of experience in this field for the optimum and stable use of star equipment. The use of special materials for the right application are ....Learn more

- Design and construction of star equipment

- For small packaging bottles

- For wide neck glasses

- For large packaging bottles

- For round bottles and shaped bottles

- For all round and shaped bottles

- External caliber, internal caliber, hold-down

- Centering for wide neck measurements

- Star rolls, exporters

- Rotation discs, drive rollers

- Wear plates

The start of a successful project begins

with your request: office@dingsleder-metallbau.at